SUPPLY CHAIN SOLUTION

The role of thecontract manufacturer is emphasized: Customers set rapidly growing and constantly changing demands for product and aftersale supply chains. The contract manufacturer needs to adapt to these changing demands and opportunities by renewing and adjusting in a dynamic working life. We’re concerned with the solution in the supply chain. Our customers are looking for a partner across the supply chain, from design to mass production, from a single test to end products after assembly and a partner using the latest technologies and tools and the means of adapt to the customer working system.

Izmet is such a partner. We work in close cooperation with our customers. We offer custom solutions that create valuable significant added value to the customer. For us, every product and every link in our customers’ supply chain is an important that guides everything we do. Therefore, Izmet is the better in contract manufacturing.

PRODUCTS

Izmet manufactures with CNC turning machine lathe machines for every metal working need for you. Our core competence is design, production and assembly of mechanics as a total service. Our solutions also cover automative, series production and testing, in housetool manufacturing, whitegoods, and maintenance of products.And also it is a provider of hydraulics metal parts for the automotive manufacturers and climate metal parts for the automotive & white good sector manufacturers.

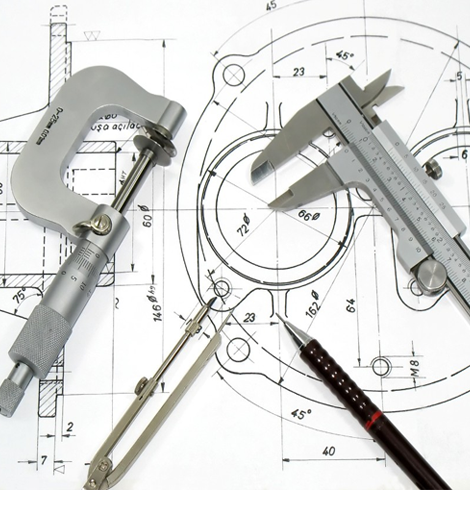

We offer a package of turning services using CNC turning centers. Automated processing control enables the company to produce parts with absolute precision in the shortest time possible.

Our skilled personnel can carry out any turning operations according to client’s drawings. Currently CNC turning machines indisputably enjoy the greatest demand. They allow performing the entire range of turning operations, namely – cutting off, lathework, threadcutting, drilling, and much, much more. Furthermore, CNC controls almost all turning works from beginning to end. Thereby, as a result, work pieces have the absolute precision and metal client’s demands.Production of Metalware:

We manufacture turning works on CNC machines according to programs of tapered, stepped, butt-end, cylindrical, and contoured (curved) surfaces of metal products. All turning works can be performed under tight deadlines. As you know, CNC machines enable us to manufacture the highest precision parts.

Production of Welded Pipe Bend

In our manufacture, our skill and ability are thin-walled pipe bends with large geometric angles. And that quality is wrinkle-free, no scratching extremely low ovality, visually aesthetic surface, each side deburred sawing edges. We apply to the raw material for carbon steel, stainless steel, nickel alloy, aluminum etc. Certainly pipe bending is a process that saves not just time, but production costs. The welded technique is also widely used in manufacturing structural and mechanical spare parts used in construction. It is simplify manufacturing process in the save materials and time. It can be finished and processed as welding, bending and flanging.

Mechanical (hardware) Assembly:

Izmet has the capability of not only manufacturing metal parts made from stainless steel, aluminum or other metal but also, we provide assembling of units depending on the process required. Attaching other non-metallic parts with different processes as established by the customer designs pecification.

Use different types of hardware or fasteners (bolts, nuts, screws, etc) to assemble multiple parts together.

QUALITY

Izmet has ISO 9001:2015 quality system certification. He started to get ISO TS 16949 QMS certification in 2020. Main focus in Izmet is continuous improvement of the processes in manufacturing metal products for automotive industry and machine industry: Better better and better for productivity, effiency and preventing defects. Our personnels are aware of VDA 6.3 main points, process indicators and targets by PPAP, FMEA, Control Plan, SPC, IMDS for raw material and the first/final control applications. We have implemented a process which motivates the staff by our motto: OUR AIM IS TO CONTINUE WİTHOUT STOPPING TO ACHIEVE PERFECTION, OF COURSE, TO GIVE THE BEST PRICE FOR OUR CUSTOMER AS OUR PARTNER.